Carburetors for Early Engines

The earliest Fairmont engines used carburetors made by Acorn. At least some of these engines, including the D and P Series, used the brass Acorn JA2. I have a 1917 build sheet for a PN engine that was originally delivered with an Acorn JA2. Here is a photo of an Acorn carburetor on a Model D1 engine.

Models JL2 and JL3

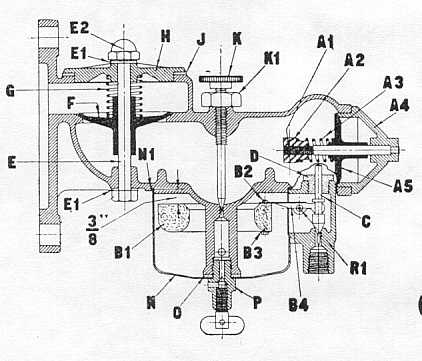

By 1926, the Fairmont JL2 carburetor for 4HP engines and the JL3 for 6HP engines were available. The poppet valves and valve seats in those days were made of metal and the air valve had 4 holes in it. Adjustment of the needle was be means of a knurled disc. Floats were cork. There was no choke originally but later model JL’s had a choke. You can see from the diagram below that the basic two-valve Fairmont design with float chamber and needle between them has been established. The one below was snagged by Eric Schwandt on ebay.

Models F4 and F6

At some time in the 1930's, the F4 and F6 models replaced the JL2 and JL3 models respectively. Shown below is an F4 I bought at a flea market a couple of years back and cleaned up.

A 1935 advertising brochure for the M19-D extolled the virtues of the F4 carburetor:

| HIGHLY DEVELOPED CARBURETOR Improved for 25 years, Fairmont carburetors are subjects of constant research to still better serve today's needs. Principally aluminum for light weight, the F4 has working parts almost ideally efficient and resistant to wear. The check and air valves are large in area, feather-light, and operate on stationary guides of tool steel. The float valve and extra large hinge pin are corrosion-resisting Monel metal: hinge pin bearing, Tobin bronze. The gasoline strainer is flushed by loosening a cap screw with the same end wrench that fits the float valve guide. Several parts, joints and gaskets are eliminated by casting the handhole cover, check valve and carburetor bodies in one piece. The float bowl and strainer head are also a unit. Gasoline leakage is prevented by the thick, cast float bowl and double width vellumoid gasket, also by the non-clogging, non-pumping air vent. All small gaskets are soft aluminum. Starting in cold weather is easy, by lifting the choke button. At way below zero, a priming cup on the throttle valve cover often starts the engine on its first turn." |

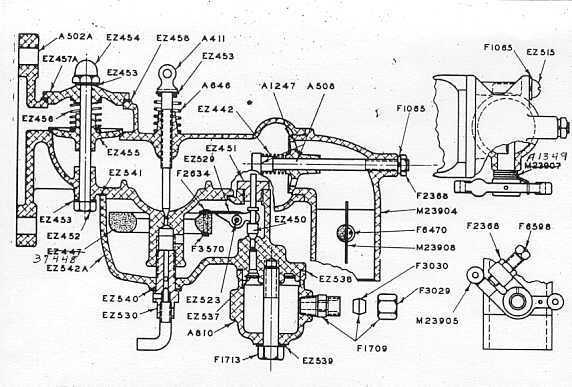

Although the above article mentions an aluminum body, I have an F6 with a steel body. This may have been one made during the war, when there were restrictions on the use of aluminum. The diagram of an A4 in an M19 manual is shown below:

Note that floats were still made of cork, there is now a choke butterfly, a separate chamber for incoming gasoline and the top of the needle valve will allow for adjustment from the control panel.

For part 2 of this story, click here.

Last Edited 28 January, 2018